Over 1 Million Linear Feet of Vitrified Clay Jacking Pipe Has Been Installed in the U.S. and Canada Since 1992.

Handling Notes

Pipe is delivered to the job site, much like bell and spigot pipe, in factory-banded packages and should be inspected prior to unloading. No-Dig pipe should be unloaded using a forklift with a rubber bumper at the back of the forks. Care should be taken to ensure the collar material, spigot ends and sealing gaskets are not damaged during unloading.

All components should be inspected again prior to placing the pipe in the jacking shaft. Both ends of each pipe should be inspected using the factory furnished dye penetrate. Apply the penetrate to the inside circumference of each pipe end using the brush provided. Immediately after the dye penetrate is applied, inspect the pipe for damage. The dye will darken any damage, making it plainly visible.

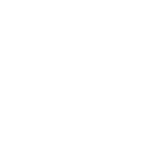

Step 1

Install the pilot tube precisely on line and grade. The existing soil is displaced during advancement of the pilot tube. The hollow stem of the tube provides an optical path for the theodolite and camera to display the head position and steering orientation on a monitor screen.

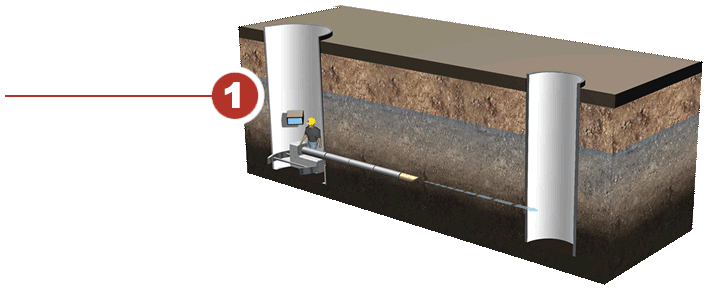

Step 2

Follow the guided path of the pilot tube with a reaming head and auger casings. The displaced soil around the pilot tube enters the reaming head and is transported to the jacking shaft for removal via auger casings. As the auger casings are installed, the pilot tubes are advanced into the reception shaft for removal.

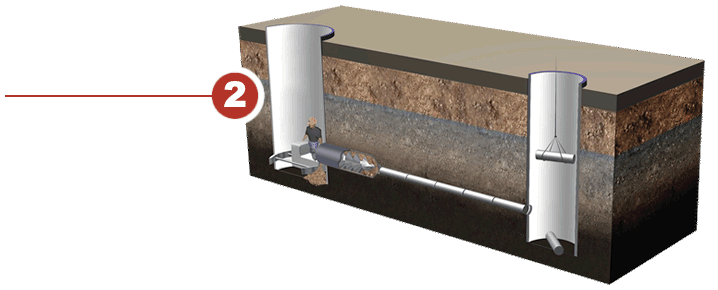

Step 3

Install the NO-DIG Pipe once the reaming head reaches the reception shaft. The reaming head and auger casings are advanced into the reception shaft by the NO-DIG pipe and removed. The completed result is a pipeline installation with the same guided accuracy as the pilot tube.

All recommendations for jacking force limits are based on “straight-line” drives, where the full jacking surface of one pipe is in contact with the full jacking surface of the previous pipe, subsequent pipe and push plate.

Any deviation from line and/or grade will significantly reduce jacking surface contact area. This deviation may concentrate the applied load over a smaller area, which will result in a reduction of the jacking force capabilities of the pipe. This deviation may result in a concentrated jacking load on the pipe.

Contact us prior to commencing any work to discuss specific questions, requirements or concerns.